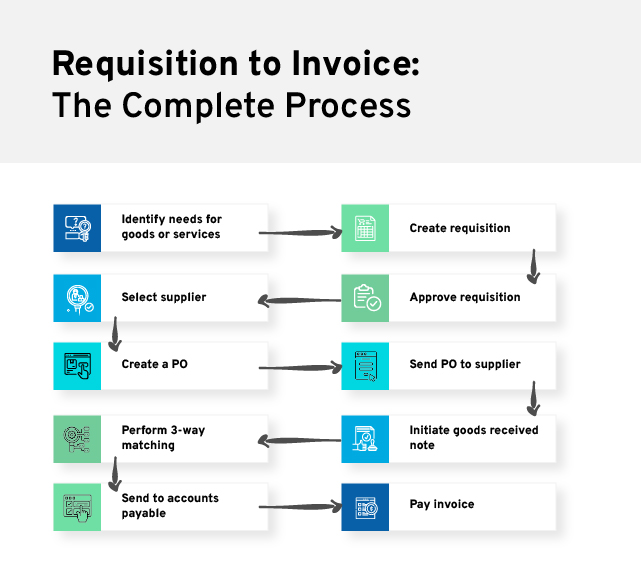

Procurement is a crucial function in any organization, and managing the process can be complex and time-consuming. From creating requisitions to tracking orders and payments, numerous, often tedious steps are involved in the purchasing process that requires careful coordination and management.

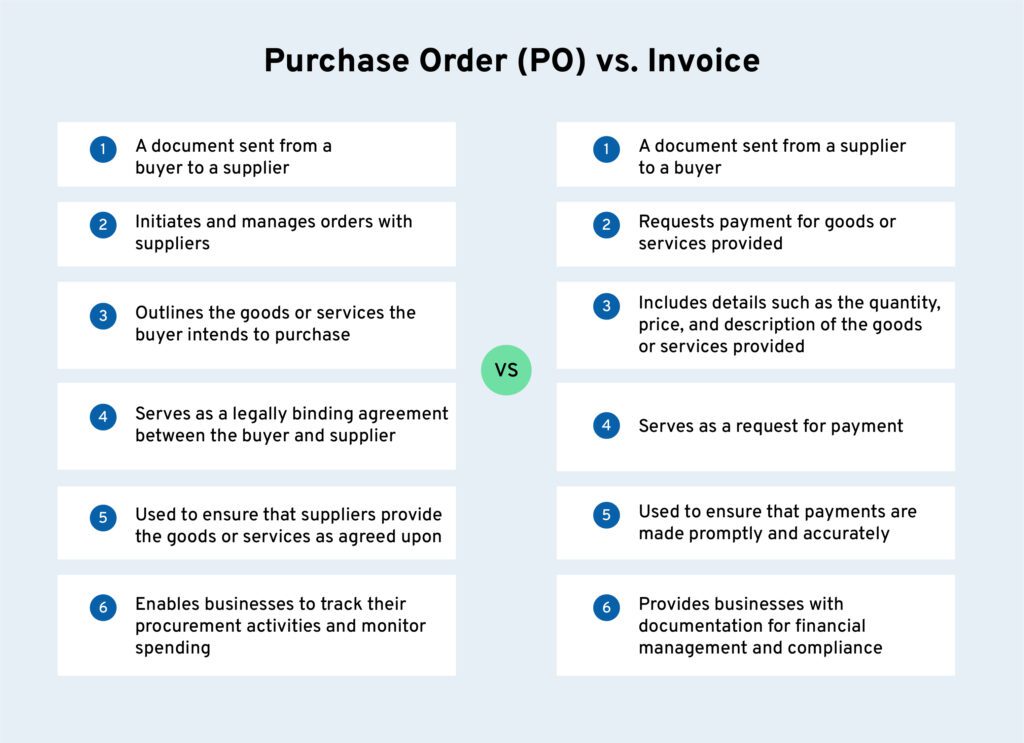

The requisition serves as the initial request for goods or services, and the tracking of the requisition ensures that the procurement process is efficient, transparent, and compliant with internal policies and external regulations.

Fortunately, procurement tracking software can simplify the procurement process and give organizations greater visibility and control over their procurement activities.

From improving efficiency to enhancing collaboration and data analysis, let’s explore the many advantages of procurement tracking software and why it is becoming an essential tool for modern procurement professionals.

Benefits of a Procurement Tracking Software

Procurement tracking software can significantly enhance the efficiency of procurement procedures by automating them, making it a valuable tool for your organization. Below are some advantages of utilizing this software:

- Enhanced Efficiency

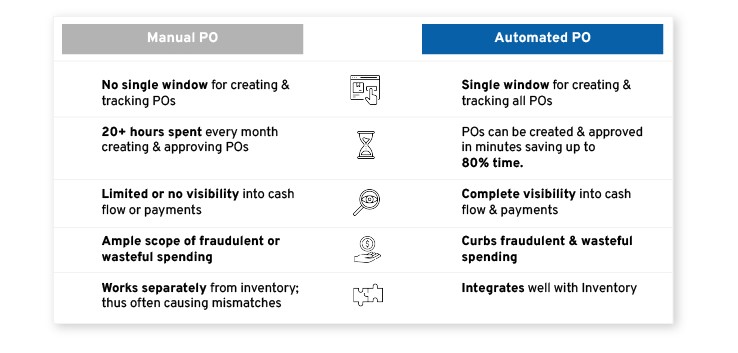

Procurement tracking software can automate your organization’s procurement processes, streamline them and reduce the likelihood of errors, delays, and manual input mistakes. This can save time and resources for organizations and improve efficiency.

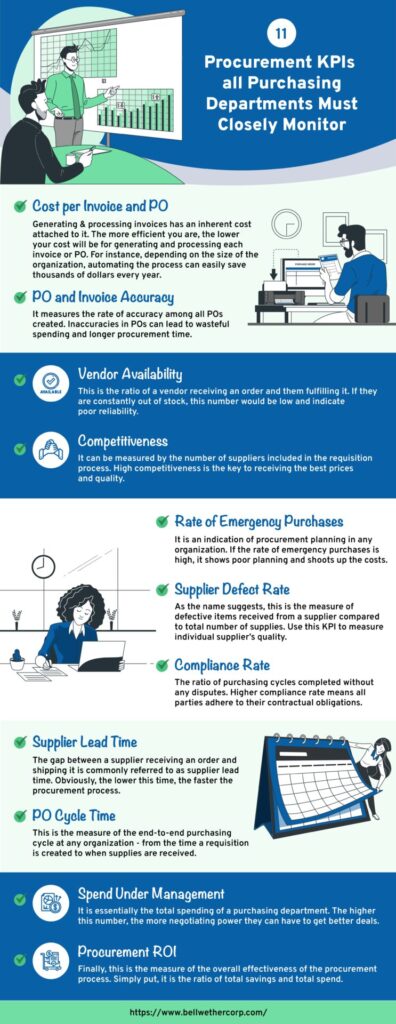

Bellwether’s digital procurement software can provide real-time insights into processes and track procurement metrics, such as lead times, delivery times, and supplier performance. For example, if there is a delay in supplier delivery times, our software can highlight this issue, allowing organizations to take action to address it. This can help your organization optimize its procurement operations, reduce costs, and identify areas for improvement.

- Better Control

Procurement tracking software provides a centralized location for tracking all procurement activities, making it easier to monitor spending, manage contracts, and track supplier performance. It also makes it easier to manage contracts and track supplier performance.

The software should be able to track contract milestones, such as expiration dates and renewal dates, and alert procurement teams when contracts are due for renewal. If the software can track supplier performance metrics, such as on-time delivery and product quality, and alert procurement teams when supplier performance falls below certain thresholds, then it is the software to choose.

- Cost Savings

With better control and automation, procurement tracking software can help organizations identify cost-saving opportunities, negotiate better pricing with suppliers, and reduce overall procurement costs.

By providing real-time insights into procurement metrics, such as spending and supplier performance, the software can help organizations optimize their procurement operations and reduce overall procurement costs. With Bellwether’s digital software, your organization can achieve better procurement efficiencies and drive better business outcomes.

- Improved Transparency

Good procurement tracking software enables organizations to achieve greater visibility and transparency in their procurement processes, reducing the risk of fraudulent activities and ensuring compliance with regulations. Efficient tracking software will allow for real-time monitoring of procurement activities in your company, making it easier to track and analyze procurement spend, supplier performance, and contract management.

With a more transparent procurement process, your company can easily prevent fraudulent activities and ensure compliance with regulatory requirements, ultimately leading to greater trust and credibility with stakeholders.

- Real-Time Reporting

Efficient procurement tracking software can enable your organization to generate real-time reports on procurement activities, providing valuable insights into spending patterns, supplier performance, and overall procurement effectiveness. Similarly, Bellwether’s procurement software will allow your organization to easily access and analyze data from different procurement activities, enabling you to identify trends, opportunities for improvement, and potential risks.

By using the insights gained from Bellwether’s software, your company can make more informed decisions and optimize its procurement operations, leading to better procurement efficiencies and cost savings. Overall, real-time reporting capabilities provided by effective tracking software can enable your organization to improve its spend management capabilities.

- Enhanced Collaboration

Improved collaboration and communication are key benefits of procurement tracking software, which provides a centralized platform for tracking procurement activities. By facilitating communication between procurement teams and other departments, the software ensures everyone is on the same page and working towards the same goals.

This collaboration also reduces the risk of errors and delays within your organization, as all stakeholders have visibility into the procurement process and can provide input as needed. With improved collaboration, your procurement teams can optimize procurement processes and maximize bottom-line profits.

- Increased Accountability

By offering an audit trail of every procurement activity, procurement tracking software promotes accountability among procurement professionals within your company. This, in turn, mitigates the risk of fraudulent practices and guarantees that all procurement procedures are executed according to internal guidelines and external regulations.

Conclusion

In conclusion, procurement tracking software is a valuable tool for organizations seeking to streamline procurement processes and achieve greater efficiencies. It enables better control, promotes collaboration between departments, and provides real-time insights for cost savings and optimized processes.

Creating a requisition and tracking it throughout the procurement process is vital for effective procurement management. It helps to improve communication, accuracy, control, efficiency, and compliance, ensuring that the procurement process is transparent, auditable, and meets all regulatory requirements.

With the ability to generate reports and enhance visibility, Bellwether’s software will help your organization reduce costs, negotiate better deals, and improve procurement operations overall. Bellwether’s digital procurement tracking software is a powerful tool that can help your organization to achieve its procurement goals seamlessly.

Get a quick demo to watch it in action!

source https://www.bellwethercorp.com/blog/benefits-of-a-procurement-tracking-software/